Machine Maintenance: Caring For Your Scissor Lift Table

A fantastic addition to any warehouse, factory, or business, the scissor lift table is a core component of modern material handling. This essential piece of lifting equipment is used across a wide array of industries to facilitate effective manufacturing, assembly, and packaging processes. To ensure these powerful tools are functioning safely and efficiently, however, proper care and regular maintenance are critical.

This guide will provide you with a comprehensive understanding of your hydraulic lift table and how to maintain it, ensuring you get the most out of your investment.

What Is a Scissor Lift Table?

Found in warehouses and production facilities across the globe, a scissor table is an indispensable tool for companies that routinely need to raise heavy goods. These tables are defined by their unique hydraulic or air-powered systems, which are attached to a criss-cross leg structure that propels the platform upwards.

These versatile lifting tables are designed solely for the movement of material goods. They come in a variety of designs and styles, offering a tailored and effective way for businesses to handle products while improving workplace safety and productivity.

The Anatomy of a Scissor Lift Table

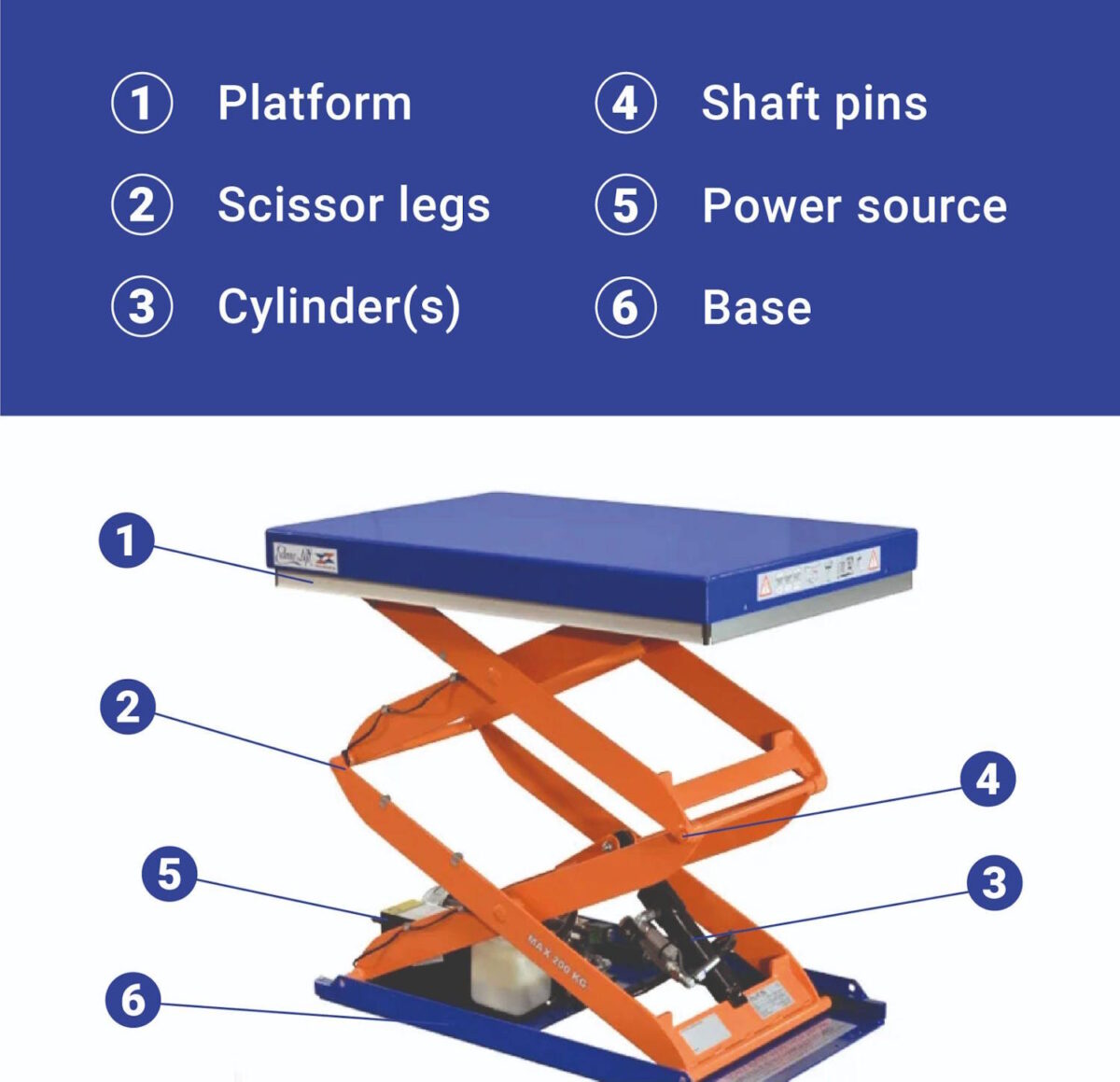

To properly maintain your scissor lift table, it’s essential to understand its key components. Knowing what each part does will help you perform effective inspections and keep your equipment in peak condition. Understanding the function of each part will enable you to conduct effective inspections and maintain your equipment in optimal condition.

- Platform: As the most visible component of a scissor lift table, the platform is the flat, level surface that provides a secure base for items as they are lifted. This stable surface ensures delicate or heavy goods remain steady throughout the lifting motion.

- Scissor Legs: Designed in a distinctive criss-cross pattern, the legs are the mechanism that drives the table’s vertical movement. This design uses powerful metal beams that take up minimal space while effectively and safely reaching height.

- Cylinders: An essential part of the lifting mechanism, cylinders are used to propel the legs upwards. Filled with air or hydraulic fluid, these systems generate the powerful thrust needed to move heavy weights with ease.

- Shaft Pins: For added stability, shaft pins are located at each intersection where the scissor legs meet. These additions ensure the legs remain securely engaged, providing an extra layer of safety during operation.

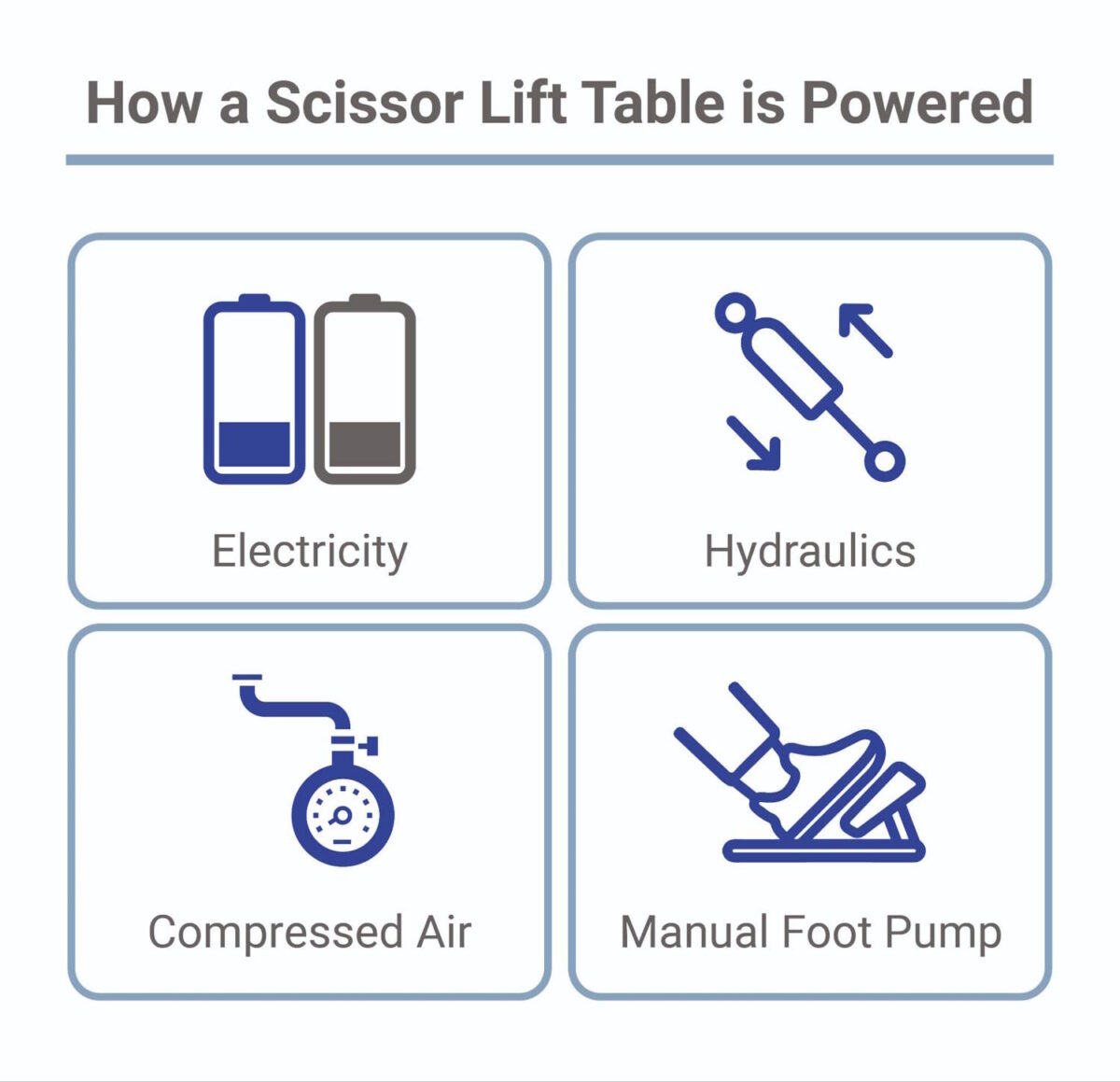

- Power Source: Each scissor lift table is powered to function, though the sources can vary. The main power source is typically housed within the base. Common power sources include:

- Electricity (via a battery)

- Hydraulics

- Compressed air

- Manual foot pumps

Base: As the most crucial part of the scissor lift table, the base is the lowermost component. It provides the overall stability needed to safely lift loads and typically houses the power source and other operational mechanisms. The base is designed to be a stationary, unmoving foundation that supports the entire weight of the lift and its load.

Proper Usage of Scissor Lift Tables

One of the best ways to keep your scissor lift fully functional is to ensure it is being used correctly and safely. Ignoring operational requirements and safety guidelines can lead to serious risks for your products, your machine, and, most importantly, your personnel.

Understanding Load Capacity

Never exceed the stated capacity of your scissor lift table. Overloading can cause irreparable damage to the system’s components and compromise its structural integrity. Always adhere to the capacity listed in the user manual to avoid serious problems.

Safety Restrictions

These tables are not designed for personnel. Unless it is a specifically designed goods-attended lift, persons should not ride on a scissor lift table. Ensuring staff does not use this equipment to stand on will both prolong the machine’s life and prevent injuries.

Adequate Training

Anyone using a scissor lift table should be fully trained on how to do so safely. Training should cover the system’s capacity, the location of emergency controls, and proper operating procedures. A well-trained workforce is a safe and efficient one.

Scissor Lift Table Maintenance

Your scissor lift table has several vital components, and regular maintenance is the key to a long, safe service life. Consistent inspections help mitigate the risk of accidents and extend the life of your equipment.

Knowing the Requirements

Different hydraulic lift tables have different maintenance requirements. Understand the power source of your lift and adjust your maintenance schedule accordingly. Be sure to check for exposed wires, leaks, or other signs of damage.

Lubrication

The movement of metal parts will naturally cause wear and tear over time. Regular lubrication is essential to prevent stiffness and erosion. Monitor all moving components for signs of rust and ensure they are properly lubricated.

Visual Defects

Don’t ignore visual defects. Perform routine visual checks for dents, bends, or other damage. Catching these problems early can prevent a minor issue from becoming a major one.

Monitor for Leaks

Leaks of fluid or gas are a major sign of a problem. Routinely inspect the cylinders, hoses, and power source for any leaks. If a leak is discovered, the system should not be used until it is addressed by a professional.

Test Emergency Controls

It is paramount that all emergency controls are fully functional. Regular testing of these systems ensures that they will work when you need them most, reducing the risk of an emergency situation.

Contact Professionals

If you notice something is wrong that you cannot address, the best course of action is to contact the experts. A trained maintenance professional can diagnose and repair any issues. We recommend routine assistance from an experienced technician, especially for intensive usage.

Other Types of Lifting Equipment

Not all lifting systems work the same way. Understanding other types of equipment can help you create a more cohesive and efficient material handling process.

Pallet Levellers: Also known as pallet positioners, these machines automatically raise, lower, or tilt pallets to keep the load at an ideal height. They are often used in conjunction with a scissor lift table to create a seamless workflow that reduces physical strain on employees.

Lifting Trolleys: Operating on a smaller scale, lifting trolleys are portable systems equipped with wheels. They allow employees to easily transport goods across a warehouse or facility, providing a safe and secure way to move products from one location to another.

Edmolift: Your Partner in Lifting Solutions

As experts in scissor lift tables and material handling equipment, Edmolift is committed to providing you with the perfect solution for your business. We understand the importance of keeping your employees safe and your operations efficient, which is why we offer only the highest quality and most reliable equipment on the market.

Ready to enhance your workplace safety and productivity? Explore our wide range of scissor lift tables and pallet levellers, or contact us directly today for expert, tailored advice on finding the ideal lifting equipment for your needs.