How To Maintain Your Electric Scissor Lift Table

Electric scissor lift tables are critical pieces of equipment for lifting and positioning heavy loads across a wide range of industries, from manufacturing and warehousing to logistics and automotive. These versatile machines, also known as scissor platform lifts, are designed to enhance workplace safety and efficiency by providing a stable and adjustable working platform. To ensure the longevity, optimal performance, and continued safe operation of your electric scissor lift table, consistent and thorough maintenance and servicing are not merely advisable, they are a must.

In this guide, we’ll delve into the best practices for maintaining electric scissor lift tables, covering routine tasks like detailed inspections, proper lubrication, and timely parts replacement. By diligently following these recommended maintenance guidelines, you can significantly extend the lifespan of your equipment, maximise its operational efficiency, and avoid costly and disruptive repairs, ultimately boosting your return on investment.

What Are Electric Scissor Lift Tables and How Do They Work?

An electric scissor lift table is a sophisticated mechanical device that uses an electric motor to power a hydraulic or pneumatic system, enabling it to precisely raise and lower heavy loads to various heights. At its core, the lift platform rests upon a series of cross-linked, scissor-like legs. When the electric motor is engaged, it drives a pump that either fills hydraulic cylinders with fluid or supplies compressed air to pneumatic cylinders which forces the scissor mechanism to extend, pushing the platform upwards. Conversely, releasing the pressure allows the legs to retract, smoothly lowering the table.

These robust scissor platform lifts are useful in a variety of industrial settings such as warehouses, assembly lines, and production facilities. By providing a safe, reliable, and ergonomic method for material handling and load positioning, electric scissor lift tables dramatically reduce the risk of manual handling injuries, contributing to a healthier and more productive workforce.

Key components of an electric scissor lift table typically include:

Platform: The flat surface where the load is placed, designed for stability.

Scissor Arms/Mechanism: The criss-cross linked supports that extend and retract to raise and lower the platform.

Hydraulic Cylinders/Pneumatic Cylinders: The power actuators responsible for the vertical movement.

Electric Motor: Drives the hydraulic pump or air compressor.

Hydraulic Power Unit: Contains the motor, pump, fluid reservoir, and control valves.

Control Unit: Allows the operator to manage the lift’s height and movement.

Base Frame: The sturdy foundation that provides stability and houses many of the core components.

Wheels/Casters: For mobility in portable electric lift table models.

Why Is Maintenance Work Important is Crucial for Your Electric Scissor Lift Table?

Routine and proactive maintenance is essential to keep electric scissor lift tables operating safely, efficiently, and consistently at peak performance. Neglecting maintenance and servicing can lead to accelerated wear and tear on key components, resulting in frequent breakdowns, costly repairs, and potential safety hazards. By conducting regular inspections and adhering to a structured maintenance schedule, you can:

- Identify Issues Early: Spot minor problems before they escalate into major, expensive failures.

- Prevent Unexpected Breakdowns: Reduce downtime and provide continuous operational flow.

- Extend Equipment Lifespan: Protect your investment by prolonging the working life of the electric scissor lift.

- Enhance Safety: Ensure all safety mechanisms function correctly, reducing the risk of accidents and injuries.

- Maintain Compliance: Guarantee your scissor lift table meets all relevant safety regulations and industry standards.

- Optimise Efficiency: Keep the platform lift running smoothly, maximising its productivity.

Understanding the Different Types of Electric Scissor Lift Table Maintenance Work

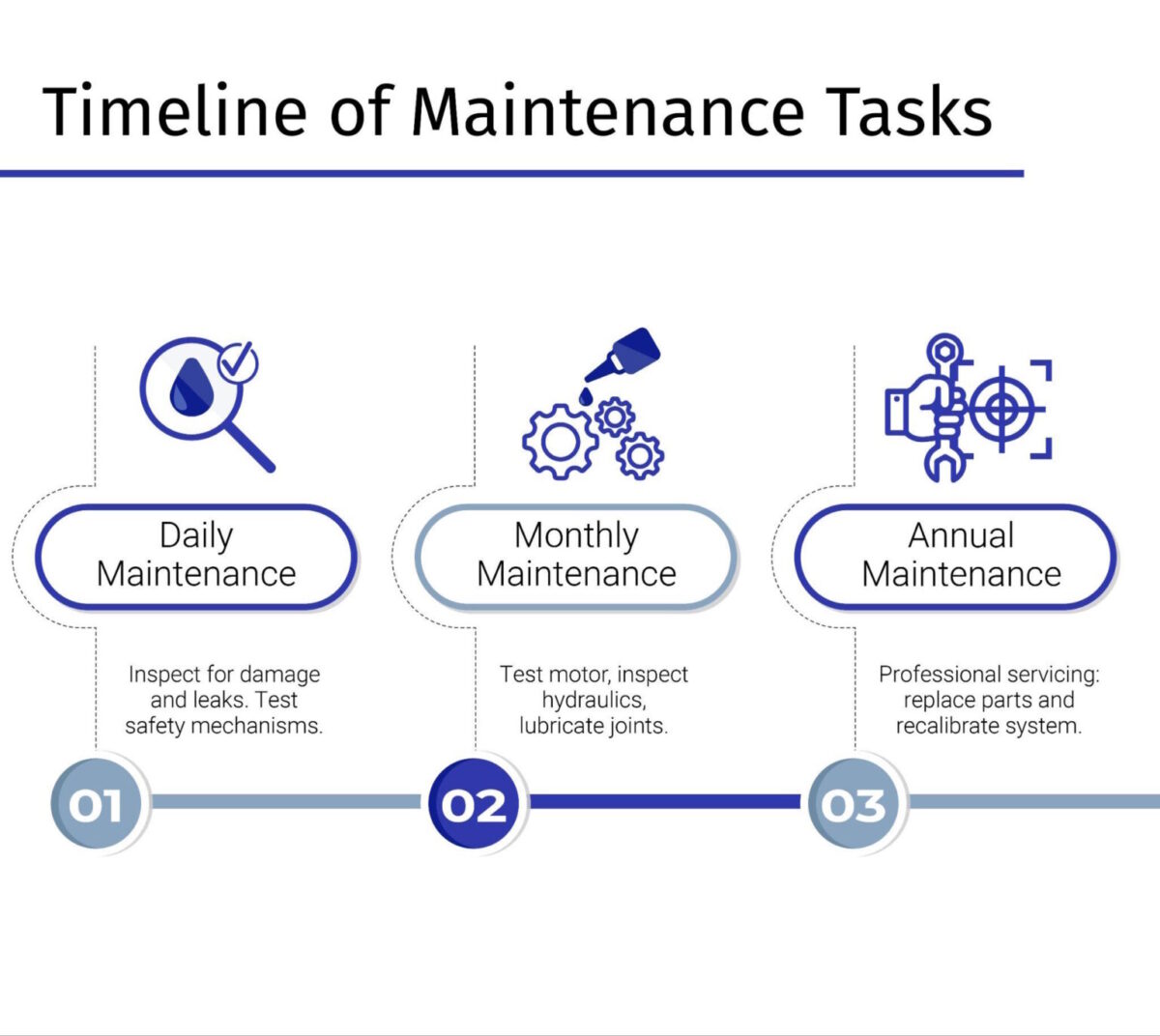

Maintenance tasks for electric scissor lift tables fall into three main categories: daily, monthly and annual, each referring to the frequency they must be carried out.

Daily Maintenance (Pre-Operation Checks):

Visual Inspections: Before each shift or use, visually inspect the entire lift table for any visible damage, wear, or leaks (hydraulic fluid or battery fluid).

Safety Mechanism Checks: Ensure all safety features, such as emergency stop buttons, guardrails, and limit switches, are functioning correctly.

Debris Removal: Clear any accumulated dirt, dust, or obstructions from the scissor arms, platform, and base.

Fluid Level Spot Check: A quick check of hydraulic fluid levels if easily visible.

Monthly Maintenance (More Thorough Checks):

Motor Inspection: Check the electric motor for unusual noises, excessive heat, or signs of wear.

Hydraulic System Inspection: More detailed checks of hydraulic hoses, fittings, and seals for leaks or damage.

Lubrication: Apply lubricant to all designated pivot points, hinges, and rollers as per manufacturer guidelines.

Electrical System Check: Inspect wiring for fraying or loose connections, and test all controls for responsiveness.

Fastener Tightness: Verify that all bolts, nuts, and fasteners are securely tightened.

Annual Maintenance (Professional Servicing):

Comprehensive Examination: A thorough inspection by a qualified technician covering all mechanical, hydraulic, and electrical systems.

Fluid Replacement: Replacement of hydraulic fluid and filters as per manufacturer’s recommendations to ensure optimal system purity and performance.

Component Replacement: Identification and replacement of any worn-out parts like bearing bushes, seals, or electrical relays.

System Recalibration: Ensuring the lift table’s systems are calibrated to meet original safety and performance standards.

Load Testing: Verification of the lift’s ability to safely handle its rated capacity.

Each stage of this structured maintenance care significantly contributes to the long-term performance, safety, and reliability of your scissor lift table, ensuring it operates dependably over time.

Essential Maintenance Tasks

Some specific maintenance tasks must be completed to keep your electric scissor lift table in proper working condition for the duration of its operational lifespan.

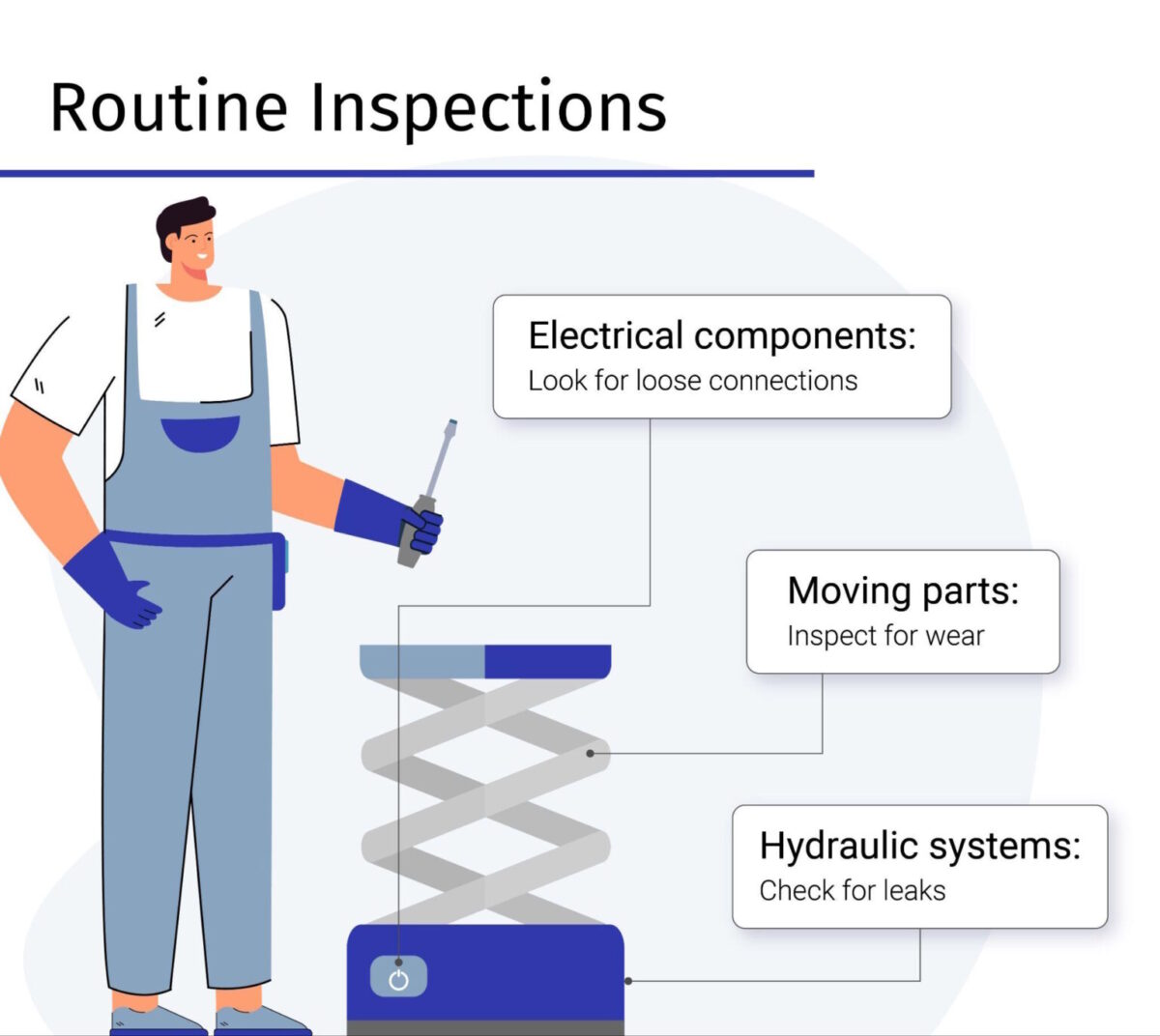

Regular Inspection

Routine inspections form the cornerstone of effective maintenance care for hydraulic scissor lift tables and electric lift tables. These checks focus on every critical aspect of the lift’s components, including:

- Moving Parts: Examine scissor arms, pivot points, rollers, and pins for excessive wear, cracks, bends, or deformation.

- Hydraulic Systems: Look for any signs of hydraulic fluid leaks around cylinders, hoses, fittings, and valves. Check for bulges, cracks, or abrasions on hoses.

- Electrical Components: Inspect wiring, connections, control panels, and switches for damage, corrosion, or loose terminals.

- Structural Integrity: Visually assess the lift platform and base frame for dents, cracks, or weld breaks. Ensure all safety decals and labels are legible.

Any irregularities detected during these inspections, no matter how minor, can significantly decrease your electric lift table’s performance and lead to breakdowns or serious safety risks if not addressed quickly and effectively. Regular inspections prevent minor issues from escalating into major problems and help to make sure the scissor platform lift table is functioning at optimal capacity.

Lubrication

Proper lubrication is critical for the smooth operation of any electric lift table. It directly impacts the lift’s efficiency, reduces downtime, and significantly extends its lifespan. Regularly apply the manufacturer-recommended lubricant to key friction points, including:

- Pivot Points: All joints where the scissor arms connect and articulate.

- Hinges and Rollers: Components that facilitate the smooth extension and retraction of the scissor mechanism.

- Hydraulic Cylinder Rods: To prevent friction and wear on seals.

Without adequate lubrication, components will experience increased friction and premature wear, leading to sluggish operation, increased power consumption, and potentially costly repairs. Always consult your electric scissor lift table’s manufacturer’s guidelines for the recommended lubrication schedule and the appropriate lubricant products to use.

Hydraulic System Maintenance

The hydraulic system is the powerhouse of most electric scissor lift tables, directly responsible for their lifting capability. Meticulous maintenance of this system is paramount:

- Fluid Level and Quality: Regularly check hydraulic fluid levels and ensure the fluid is clean and free of contamination. Contaminated fluid (e.g., with water or particulates) can severely damage internal components. Only use the type and grade of hydraulic fluid specified by the manufacturer.

- Hose and Fitting Integrity: Inspect all hydraulic hoses, fittings, and connections for leaks, cracks, bulges, or signs of wear. Replace any damaged components immediately.

- Filter Replacement: Hydraulic systems often include filters to keep the fluid clean. Replace these filters according to the manufacturer’s recommendations to prevent contaminants from damaging critical hydraulic components like pumps and valves.

- Cylinder Seals: Monitor hydraulic cylinders for any signs of external leakage, indicating worn seals that may require replacement.

Maintaining the hydraulic system diligently prevents lifting issues, ensures the table functions correctly, and is vital for smooth, reliable lifting, contributing to long-term efficiency and safety.

Safety Mechanisms

The safety features integrated into an electric scissor lift table are designed to protect operators and prevent accidents. These mechanisms must be checked regularly to ensure they function precisely as intended:

- Emergency Stop Buttons: Test both the platform and ground-level emergency stop buttons to ensure they immediately cut power to the lift.

- Limit Switches: Verify that upper and lower travel limit switches activate correctly to prevent over-extension or over-lowering.

- Safety Rails/Gates: Ensure guardrails are secure and entry gates close and latch properly.

- Overload Protection Devices: While not always manually testable without specialized equipment, be aware of their presence and functionality; they prevent the lift table from attempting to lift loads beyond its rated capacity.

- Hose Burst Valves: Many hydraulic cylinders are fitted with these to prevent rapid uncontrolled descent in case of a hose rupture. Ensure these are in place and undamaged.

Any malfunctions in these critical safety features should be addressed immediately. Prompt action is paramount to maintain a safe work environment and prevent workplace injuries or costly damage to the lifting equipment.

Cleaning and Debris Removal

Keeping the electric scissor lift table clean is another often-underestimated but crucial part of comprehensive maintenance. Accumulations of debris, dirt, metal shavings, or other foreign materials can significantly interfere with the lift’s operation, causing friction, wear, and even mechanical jams.

- Regular Cleaning: Implement a schedule for thoroughly cleaning the entire scissor platform lift, paying particular attention to the scissor arms, pivot points, platform surface, and the area around the hydraulic unit.

- Obstruction Removal: Ensure no obstructions are present within the scissor arms’ operating envelope, which could impede movement or cause damage.

- Platform Cleanliness: Keep the lift platform clean and free from oil, grease, or other contaminants that could create slip hazards or damage materials.

A well-maintained and clean scissor platform lift table not only looks better but also operates more reliably and lasts longer, directly contributing to its extended lifespan.

Professional Servicing

While regular in-house daily and monthly maintenance can prevent and detect many common issues, professional servicing by qualified technicians is essential for a more thorough inspection, advanced diagnostics, and expert repair.

- Expert Assessment: Certified technicians possess the specialised expertise and knowledge to assess the electric lift table’s overall condition, identify underlying issues that might not be obvious during routine checks, and perform complex adjustments.

- Component Replacement: Professionals can expertly replace worn or damaged parts, often having access to genuine manufacturer parts, ensuring optimal compatibility and performance.

- Compliance Assurance: They ensure your lifting equipment remains compliant with current industry standards and safety regulations, providing necessary certifications or documentation.

- Preventative Diagnostics: Professional servicing often includes diagnostic tests that can predict potential failures before they occur, allowing for proactive intervention.

This level of in-depth inspection and servicing should be scheduled annually as a minimum to fine-tune the electric scissor lift table for peak performance and ensure its long-term reliability and safety. Professional maintenance is your strongest safeguard against major breakdowns and guarantees the longevity of your electric scissor lift table.

Replacements

Certain components of your electric scissor lift table are subject to wear and tear over time and should be replaced proactively after extensive use, even if they appear to be functioning. These include:

- Hydraulic Valves: Can wear out, leading to sluggish or inconsistent operation.

- Electrical Relays: May degrade over time, causing intermittent electrical issues.

- Bearing Bushes/Pivot Pins: Critical for smooth scissor arm movement; worn bushes can lead to misalignment and increased friction.

- Seals and Gaskets: Within hydraulic cylinders and the power unit, these prevent leaks and maintain system pressure.

It’s often recommended to replace these components based on operating hours or lift cycles (e.g., every 200,000 lift cycles for certain parts), as specified in the manufacturer’s maintenance manual.

Electric Scissor Lift Table Maintenance Top Tips

In conjunction with the necessary routine inspections and professional servicing, incorporating these additional tips into your operational practices can further help you maximise the efficiency, safety, and longevity of your electric lift table:

Consult Manufacturer Information

Every electric lift table comes with comprehensive documentation, including detailed instructions for recommended maintenance tasks. These guides contain invaluable information, detailed explanations, diagrams, and images to help operators and maintenance personnel carry out essential upkeep effectively. Always refer to your specific model’s manual for precise guidelines.

Thorough Documentation and Record-Keeping

Maintaining detailed records of all maintenance tasks, inspections, repairs, and component replacements is crucial.

- Tracking Maintenance Schedules: Helps you stay on track with planned maintenance and servicing.

- Identifying Recurring Issues: Allows for quick identification of persistent problems that may indicate a larger underlying issue.

- Ensuring Compliance: Provides a clear audit trail for safety regulations and warranty requirements.

- Valuable Reference: Offers a historical record for future maintenance and servicing work, aiding troubleshooting and long-term planning.

Comprehensive Training and Operator Awareness

Proper training is essential for maintaining a safe and effective environment when working with scissor platform lift tables. Operators should be thoroughly knowledgeable about:

- Safe Operation Procedures: How to correctly and safely operate the lift table

- Pre-Operation Checks: The importance and methodology of daily inspections

- Spotting Early Signs of Wear/Malfunction: What to look for and how to report issues promptly.

- Safety Protocols: Adherence to all workplace safety guidelines.

- Load Capacity Limits: Understanding and never exceeding the specified weight capacity of the scissor lift.

Well-informed and consistently trained operators are fundamental to ensuring the longevity, safety, and optimal performance of electric scissor lift tables in any operational setting.

Find Your Ideal Scissor Lift Table

At Edmolift, we pride ourselves on delivering durable, reliable, and highly efficient lifting equipment, ranging from high-performance electric scissor lift tables to specialised lift and tilt tables. Our knowledgeable team is always available to provide expert guidance on all aspects of electric scissor lift table maintenance, ensuring your platform lift stays in optimal condition. For more information about our products, comprehensive services, or expert maintenance advice, get in touch with our team today.