A lift table is a stationary mechanical device used for material handling and positioning by raising and lowering heavy loads. Lift tables are used in a variety of industrial settings like manufacturing plants, factories or warehouses.

There are various types of lift tables so choosing the right lift table can seem complicated. In this article, we’re going to look at the different types of lift tables and the considerations you should make to pick the right lift table for your business.

What Are The Different Types Of Lift Tables?

Although lift tables are similar, some use different mechanisms to raise or lower goods and have contrasting features.

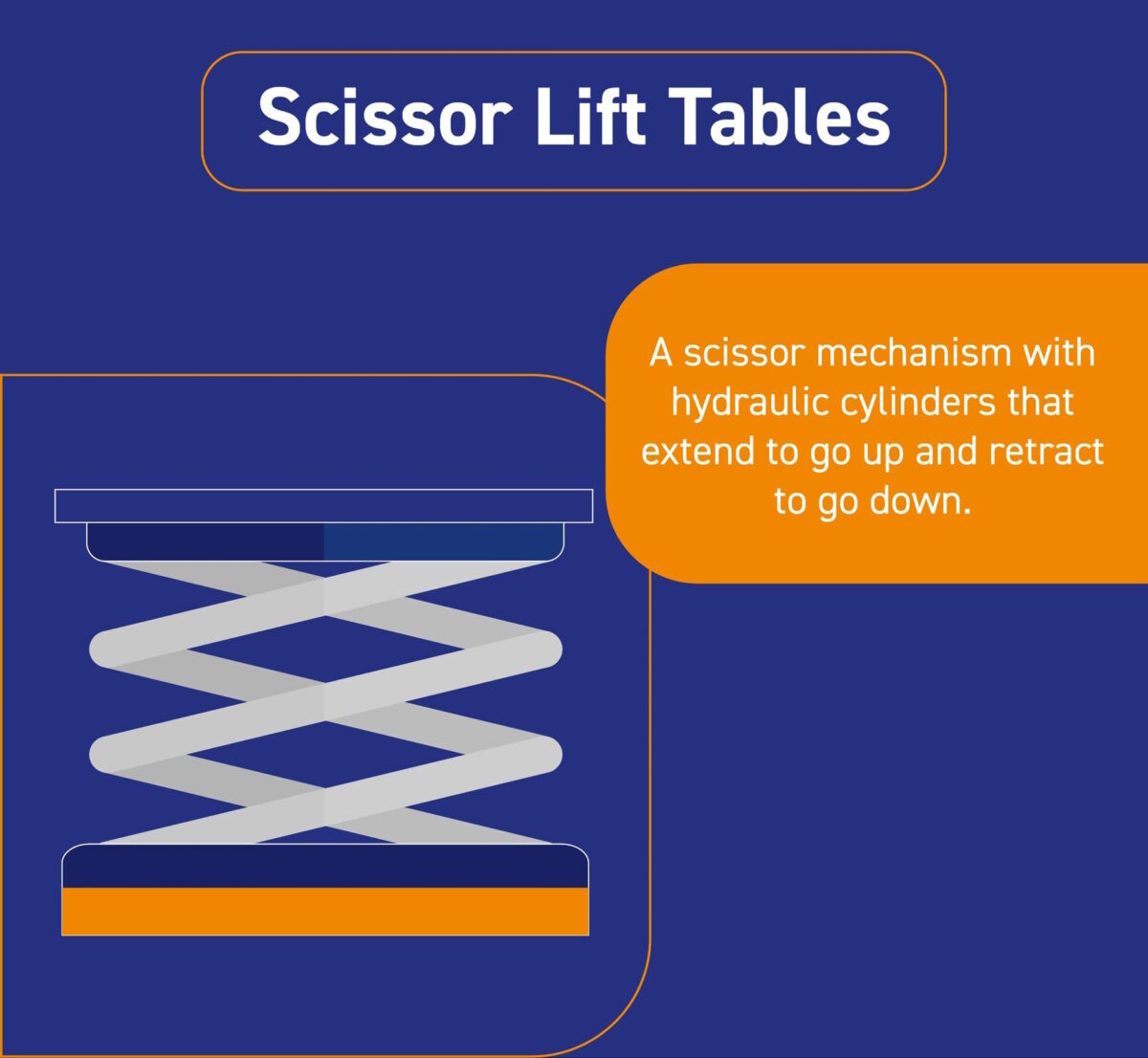

Scissor Lift Table

Scissor lift tables, also known as Hydraulic lift tables come in a variety of different options to fit the needs of different uses and applications, these include:

- Single Scissor

- Double / Triple Vertical

- Double Horizontal

- Low Profile

- Heavy Duty

- Stainless Steel

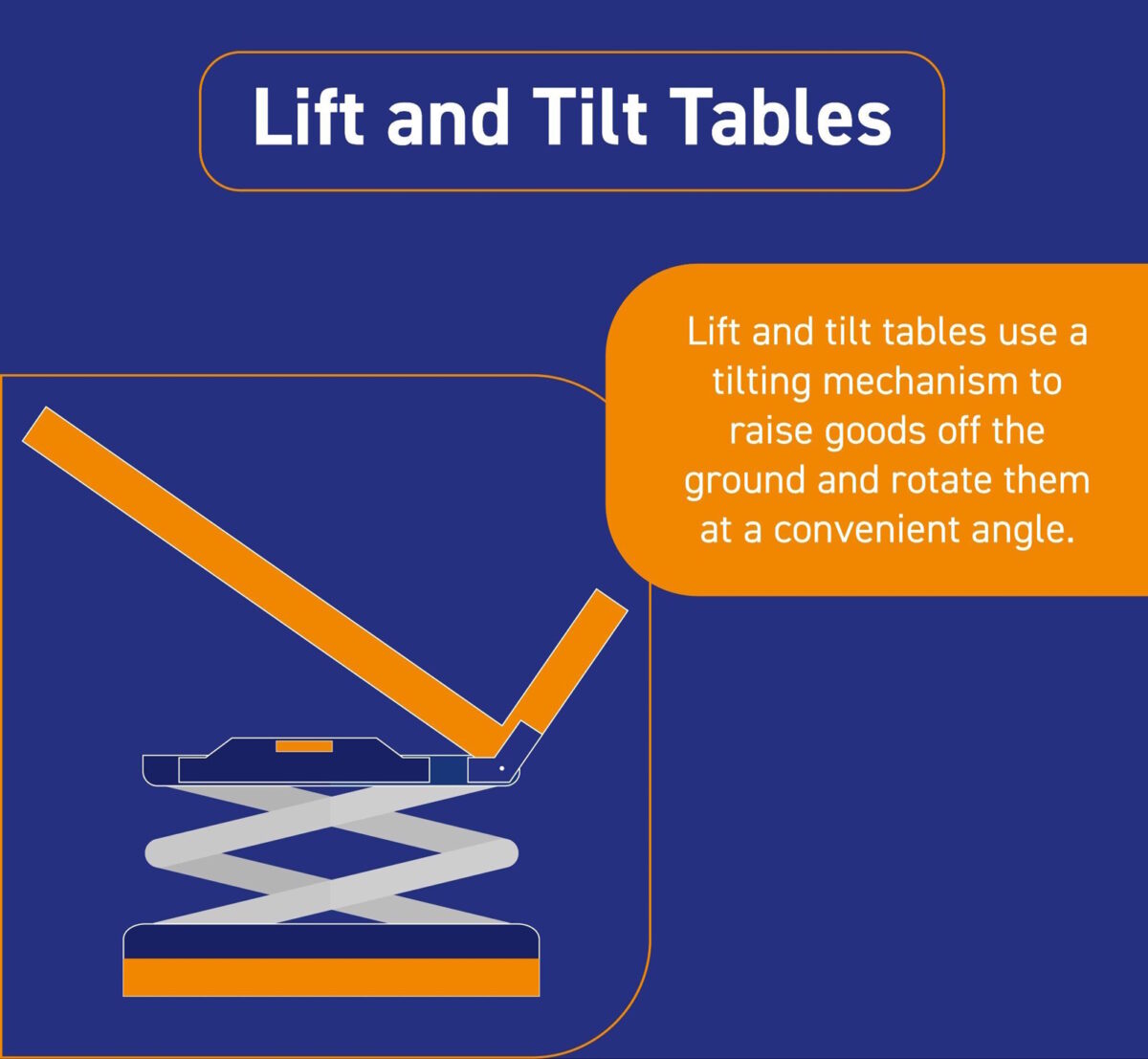

Lift and Tilt Table

Lift and tilt tables use tilting devices installed directly on the floor with a base frame and power pack. The tilt function is used to incline the platform and make the load more accessible for a more ergonomically functional workplace.

Why Does My Business Need A Lift Table?

Lift tables can be useful in a variety of settings where a business would benefit from a stationary device to raise or lower items off the ground.

Lift tables feature an ergonomic design to place a load at a convenient level for workers. Positioning materials at the ideal height prevents the need for physical lifting or bending, which can result in employees getting injured.

Scissor bars allow the weight of the load to be distributed evenly. This reduces the risk of the load falling and becoming damaged or harming nearby workers.

Other uses include:

- Multi-level handling or assembly

- Vehicle loading and docking

- Loading or unloading pallets

- Work positioning and material handling

How Do I Choose The Right Lift Table For My Business?

Lift tables come in all shapes, sizes, and weight capacities to cater for different uses. When deciding which lift table is right for your business, you need to consider the needs of your operations.

Platform Size

Knowing the dimensions of the loads you intend to lift will help you decide which size scissor lift platform is needed. If you plan to transport long and heavy goods, a horizontal double-scissor table lift may be most suitable due to its elongated scissor platform.

Lifting Height

Lift tables are available with different height capabilities. Single-scissor mechanisms are the standard lift table, which offers a powerful yet versatile use. Vertical double or triple-scissor mechanisms feature a number of scissor arms assembled vertically on top of each other to provide a greater lifting height.

Weight Capacity

Industrial lift tables have different load capacities. Depending on the maximum weight of the items you intend to lift, you should choose a lift table capable of carrying this weight.

HD-Series Heavy Duty lift tables meet the toughest category of lift table standard EN 1570-1, category 5. This lift type provides maximum strength and stability and is intended to run constantly for uninterrupted operations.

Safety Features

Certain lift table models are manufactured to comply with the requirements of different industries. For example, stainless steel lift tables have high corrosion-resistant steel under standard AISI 316/EN 1.4301 (SS 2333). This industrial lift table is ideal for the food, chemical or pharmaceutical industry or where a high level of hygiene is required.

Folded Height

Once the lift table contracts, it takes up less space. If your lift table needs to fit in a particular space, take measurements of the area and use these dimensions to decide which lift table will fit.

Mobility

Scissor lift platform tables are generally stationary and should be kept in a fixed position. If the lift table needs to be moved to multiple locations, a mobile scissor lift table would be the most beneficial option.

Customisation

Scissor lift tables can be produced in many different colours according to customer requirements and branding. There is also a range of accessory customisation and control alternatives to suit client preferences. Several models are available in a durable format suitable for intensive operations.

Trusted Supplier and Warranty

Make sure you purchase from a reputable supplier to ensure lift tables are high-quality. Research reliable lift table suppliers and read through customer testimonials to see if feedback is positive.

Lifting equipment is made to last, a sign of a trustworthy supplier is providing a lift table warranty and ongoing customer support. This guarantees that should the lift table malfunction, the supplier is responsible for repairing or replacing the item.

Certifications and Regulation Compliance

All machinery sold in the European Economic Area (EEA) must be marked with CE to demonstrate that it conforms with EU health, safety and environmental standards.

Edmolift

At Edmolift, we’re Europe’s largest manufacturer of scissor lift platform tables and the UK’s biggest lift table supplier. Established in Cambridge in 1964, industry professionals have depended on our services for 60 years.

With decades of experience providing expert advice and support to companies in industrial settings, we offer an extensive range of standard smart lift tables and bespoke solutions that are tailored to the needs of your business and its premises.

We design and manufacture our lift tables according to our core values; quality, reliability and innovation. We offer a three-year warranty on our parts and labour and a five-year structural guarantee to give you peace of mind that our lift tables are made to last.

For more information about our electric lift tables, call Edmolift at 01440 730640 or contact us online.