The Buyer’s Guide to Choosing a Scissor Lift Table

In industrial environments, a scissor lift is a vital link in your production chain. Getting the specification wrong creates a ripple effect of bottlenecks, safety risks, and wasted capital. To get the best return on your investment, you need to look past the surface and focus on the engineering that keeps the gears of industry turning.

This guide breaks down the technical variables that matter most when choosing a scissor lift table.

Matching the Mechanism to the Space

The first step is a simple ratio: how much height do you need versus how much floor space do you have?

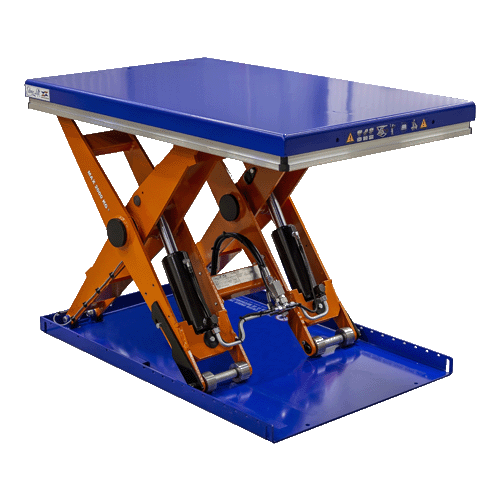

Single Scissor Tables

These are the industry standards for most production lines and workstations. They are ideal when the lift height is relatively low compared to the length of the platform. Because single scissor lift tables have a lower centre of gravity, they offer maximum structural rigidity, which is crucial for tasks requiring high precision or where operators are working directly on the platform.

Multi-Vertical Scissors (Twin or Triple)

When you need to reach a mezzanine or a high loading dock but have a small footprint, you might need a multi-vertical scissor table. While this saves space, it changes the physics of the lift. As the height increases, lateral stability becomes the main concern. We engineer these units to minimise deflection (that is, the slight sway you might feel at full extension), making sure the lift remains rock-solid even at its peak.

The Physics of the Load

One of the most common mistakes made when choosing the correct scissor lift table is looking only at the total weight capacity. A 2,000kg load is not just a number; it is a force that needs to be managed.

Dead Weight vs. Live Loads

- Dead Weight: This is the static mass of the object sitting still on the platform.

- Live Loads: These are the dynamic forces. Think about a worker driving a powered pallet truck onto the platform and hitting the brakes. That sudden shift in momentum creates a force much higher than the static weight of the truck. If your lift isn’t built to absorb that impact, you’ll see structural fatigue within months.

The Problem with Point Loads

Most standard tables are rated for an Evenly Distributed Load (EDL). But in reality, loads are often concentrated on small points, like the four wheels of a heavy trolley. This causes the platform surface to warp or bow (a defect known as dishing), which puts uneven pressure on the underlying structure and can lead to hydraulic failure. We solve this by reinforcing the platform with high-tensile steel to ensure the surface stays flat and the hydraulic seals remain protected from uneven pressure.

Duty Cycles: Why 24/7 Operations Need the HD-Series

The lifespan of a lift is measured in cycles, not years. If you buy a standard lift for a 24/7 distribution centre, it will fail. Most standard tables are built for intermittent use, roughly 10 to 20 cycles per hour.

Enter the HD-Series

For high-frequency environments, you need a heavy-duty (HD) build. These units are engineered for constant motion.

- Heat Management: In 24/7 loops, hydraulic oil heats up. When oil gets too hot, it thins, leading to jerky movements and seal failure. HD units use high-performance cooling profiles to keep the system stable.

- Reinforced Components: We use oversized, greaseable bearings and hard-chrome plated pins. These parts are designed to be serviced and kept in the field for decades, rather than being replaced.

Power Systems: 3-Phase vs. 1-Phase

The drive system is the heart of the lift. While it’s tempting to plug into a standard socket, industrial applications usually require more muscle.

3-Phase (400V)

This is the gold standard for any serious operation. It provides consistent torque, runs cooler, and allows for significantly faster lifting speeds. If your facility has the infrastructure, 3-phase is always the right call for productivity.

1-Phase (230V)

These are better suited for light-duty workshops or sites where 3-phase isn’t available. They are perfectly capable, but they require longer “rest” periods between cycles to prevent the motor from overheating.

Pit Installs and Safety

A lift has to play well with its environment. If you are installing a lift into a floor pit to keep it flush with the ground, you have to plan for more than just the hole in the floor.

- Drainage: Pits collect dust, debris, and water. Without a proper drain, your hydraulic power pack is sitting in a swamp.

- Maintenance Access: Every lift needs a check-up. We design our units with specific service hatches and safety stay bars, so your team can work safely without removing the entire unit from the pit.

- Safety Perimeters: To protect your team from shear points, we recommend PVC bellows or mesh curtains. These keep toes (and stray tools) out of the scissor mechanism.

The Edmolift Standard

At Edmolift, we know that choosing a lift is all about precision. It’s about knowing the difference between a machine that just works and a machine that thrives under pressure. With over 30 years in the field, we’ve seen every possible application, from pharmaceutical cleanrooms to heavy-duty aerospace assembly.

When you choose a lift, you are choosing the foundation of your material handling. Make sure that the foundation is built on technical expertise and a deep understanding of your operational stressors. Contact us today to find out how we can help you select the right scissor lift table for your requirements.