Low Profile Scissor Lift Tables: The Ultimate Solution for Small Businesses

May 21, 2025

How To Maintain Your Electric Scissor Lift Table

May 21, 2025How to Properly Operate an Electric Scissor Lift Table

In the dynamic environments of warehouses, workshops, and manufacturing plants, the twin pillars of efficiency and safety are non-negotiable. Seamless processes and a secure workspace are paramount, especially when dealing with the inherent risks of industrial operations. Among the most common and valuable tools found in these settings are electric scissor lift tables. These powerful machines are designed to dramatically improve productivity, but their immense utility comes with the crucial caveat of requiring safe and cautious operation.

In this post, we will delve into the reasons why safety is not just a recommendation but an absolute necessity when using scissor lift tables.

Understanding Electric Scissor Lift Tables

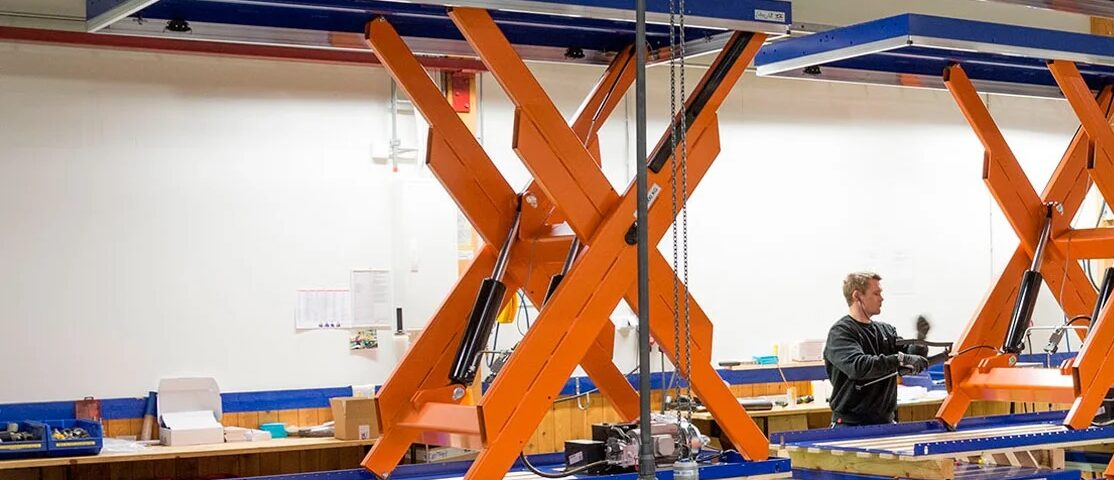

A scissor lift table is a robust lifting solution engineered specifically for the vertical raising and lowering of heavy loads. These versatile machines are cornerstones in industrial environments such as vast warehouses, bustling manufacturing plants, distribution centres and various other workplaces where the precise and efficient movement of cargo between different heights is a daily requirement.

It’s vital to clarify a common misconception: unlike a personnel-carrying scissor lift (often referred to simply as a “scissor lift” or “aerial work platform”), electric scissor lift tables are purpose-built for material handling. Their primary function is to transport heavy goods, components, pallets, and other cargo, not people. This distinction is critical for understanding their design, safety protocols, and operational limitations.

The ingenuity of an electric scissor lift table lies in its distinctive scissor-like mechanism. This series of interconnected supports expands and contracts, much like a pair of scissors, to elevate or descend the platform. The entire operation is powered by a reliable electric motor, which provides the necessary force to lift substantial weights with remarkable precision and controlled movement. This scissor lift mechanism allows workers to position items with accuracy, whether loading a truck, feeding materials to a production line, or stacking goods in a storage area. The smooth, controlled motion lessens the risk of damage to goods and ensures a safer working environment.

Integrating scissor lift tables into your operational flow can deliver a wide array of benefits, significantly impacting both your bottom line and the well-being of your workforce.

The Multifaceted Benefits of Scissor Lift Tables

Integrating scissor lift tables into your operational flow can deliver a wide array of benefits, significantly impacting both your bottom line and the well-being of your workforce.

- Minimising Labour Efforts and Preventing Injuries: One of the most significant advantages of a scissor lift table is its ability to reduce the need for manual lifting. This directly translates to less physical strain on employees, drastically lowering the risk of musculoskeletal injuries, back strains, and other common workplace accidents associated with heavy lifting.

- Speeding Up Lifting Tasks and Improving Workplace Productivity: Manual lifting is slow, inefficient, and often requires multiple employees. Scissor lift tables mechanise this process, allowing for quicker loading, unloading, and positioning of goods. This acceleration of tasks directly contributes to improved throughput and overall workplace productivity, enabling your team to accomplish more in less time.

- Enhancing Ergonomics and Worker Comfort: Scissor lifts are ergonomically designed so that workers can use the adjustable height to reduce bending, reaching, and awkward postures. This improved ergonomics leads to greater comfort, less fatigue, and ultimately, a more engaged and productive workforce.

- Low Maintenance Costs and Long-Term Value: Designed for industrial environments, most electric scissor lift tables are built with robust components and durable construction, ensuring longevity. Their electric operation typically means fewer moving parts than hydraulic lift tables, often resulting in lower maintenance requirements and operational costs over their lifespan, making them a wise long-term investment.

- Adaptability Across Diverse Applications: The versatility of scissor lift tables is remarkable. They are not confined to a single task but can be adapted for numerous applications, including:

- Loading Docks: Facilitating the smooth transfer of goods from trucks to warehouse floors.

- Assembly Lines: Positioning components at optimal working heights for technicians.

- Palletising/Depalletising: Making loading and unloading processes of goods safer and faster.

- Work Positioning: Providing adjustable platforms for maintenance, repairs, or specialised tasks.

- Ergonomic Workstations: Creating customisable workstations that adjust to individual worker heights and task requirements.

Safe Operation Guidelines for Your Scissor Lift Table

While scissor lift tables are engineered to provide a safer means of material handling, their very power and capacity mean that improper operation carries significant risks. When dealing with heavy-duty equipment and substantial loads, vigilance is paramount. Neglecting safety protocols can lead to serious injuries, costly equipment damage, and significant operational downtime. Understanding these potential dangers is the first step towards preventing them.

Here are some of the critical factors that can compromise the safety of scissor lift tables:

Unstable or Uneven Surface Conditions: Operating a scissor lift table on any surface that is not level, firm, and capable of supporting the combined weight of the table and its maximum load is a catastrophic risk. An uneven surface can cause the table to become unstable, leading to a dangerous tip-over. Even minor inclines or soft spots in the ground can create a hazardous situation. Always ensure the operating area is thoroughly inspected and verified as stable.

Improper Load Distribution: The way goods are placed on the scissor lift table platform directly impacts its stability. If the weight of the cargo is not evenly distributed across the platform, or if the centre of gravity is too high or off-centre, the table can become unbalanced and prone to tipping. Always place the heaviest items in the centre and distribute the load symmetrically.

Exceeding Weight Capacity (Overloading): Every scissor lift table has a clearly defined maximum weight capacity. Ignoring this critical specification and attempting to lift loads heavier than the rated capacity is incredibly dangerous. Overloading can lead to structural failure, hydraulic system malfunction, motor burnout, or even a sudden collapse of the platform, resulting in severe injuries or fatalities. Always verify the weight of the load before attempting to lift it.

Unsafe Surrounding Areas and Obstructions: The operational zone around a scissor lift table must be kept clear and safe. This includes maintaining adequate clearance from overhead power lines, which pose electrocution hazards. Furthermore, ensure the area is free from moving vehicles, forklifts, other machinery, or personnel that could collide with the table. Barriers or clear markings should be used to define the safe operating zone.

Inadequate Operator Training and Certification: This is arguably the most critical safety factor. Allowing untrained or unqualified personnel to operate a scissor lift table is an unacceptable risk. Operators must possess a comprehensive understanding of the equipment’s functions, limitations, safety features, and emergency procedures. Proper training ensures operators can identify hazards, react appropriately, and perform tasks safely.

Safe Operation Guidelines

To guarantee the safety of both personnel and valuable cargo, rigorous adherence to pre-use and operational guidelines is essential when working with scissor lift tables. Implementing these protocols systematically will significantly reduce risks and foster a culture of safety within your facility.

Pre-Use Safety Checks

Before any scissor lift table is powered on for the day’s tasks, these fundamental pre-use principles must be meticulously carried out:

- Mandatory Operator Training and Certification: This is the cornerstone of safe operation. All personnel designated to operate a scissor lift table, or any form of heavy-duty lifting equipment, must undergo comprehensive, certified training. This training should cover:

- Equipment Familiarisation: Understanding all controls, safety features, emergency stops, and maintenance points.

- Hazard Identification: Recognising potential dangers like unstable surfaces, overhead obstructions, and load imbalance.

- Safe Operating Procedures: Step-by-step instructions for loading, lifting, lowering, and emergency protocols.

- Regulatory Compliance: Awareness of all relevant health and safety regulations (e.g., OSHA, PUWER, LOLER).

- Practical Hands-On Experience: Supervised practice to build proficiency and confidence.

- Refresher Training: Regular refresher courses to reinforce knowledge and address any new equipment or procedures. It’s not enough for staff to know about hazards; they must also be trained on how to properly respond in the event of an incident, including emergency shutdown, evacuation procedures, and first aid.

- Selecting the Right Scissor Lift Table for the Task: Scissor lift tables come in various sizes, capacities, and power sources (electric, hydraulic, manual). Before commencing any lifting operation, it is essential to confirm that the chosen scissor lift table is perfectly matched to the specific requirements of the job. This involves:

- Weight Capacity Verification: Checking that the table’s maximum load capacity comfortably exceeds the actual weight of the item(s) to be lifted.

- Platform Size Suitability: Ensuring the platform is large enough to safely accommodate the load without overhangs or unstable positioning.

- Lift Height Requirements: Confirming the table can reach the necessary height without being over-extended.

- Environmental Compatibility: Considering factors like indoor/outdoor use, power source availability, and manoeuvrability in confined spaces. Using an undersized or unsuitable table dramatically increases the risk of accidents.

- Thorough Pre-Operational Visual Inspection: A meticulous visual inspection of the scissor lift table before each shift or use can prevent a multitude of problems. Operators should systematically check the following:

- Structural Integrity: Look for any visible signs of damage, cracks, dents, or deformations on the frame, platform, or scissor mechanism.

- Hydraulic/Electric Systems: Check for any fluid leaks (hydraulic fluid, battery acid), damaged hoses, frayed cables, or exposed wiring.

- Fasteners and Connections: Ensure all bolts, pins, and connecting components are secure and not loose or missing.

- Wheels/Casters: Inspect for damage, proper inflation (if pneumatic), and ensure they rotate freely and are not seized.

- Safety Features: Verify that all safety guards, warning decals, emergency stop buttons, and safety alarms are present, functional, and visible.

- Controls: Test all operational controls (up, down, emergency stop) to ensure they respond correctly.

- Any identified issue, no matter how minor, should be immediately reported to a supervisor, and the scissor lift table should be tagged out of service until repaired by a qualified technician.

Operating Guidelines

Once the pre-use safety procedures are complete and the scissor lift table is deemed fit for operation, adherence to these guidelines is paramount:

- Mastering Proper Loading and Unloading Techniques: This is a frequent point of failure and requires constant attention.

- Weight Verification: Even after initial checks, operators should always have an estimate of the load’s weight and confirm it is within the table’s capacity.

- Even Weight Distribution: Loads must be centred on the platform. Avoid placing items too far to one side or end. If multiple items are being lifted, distribute their weight evenly across the platform to maintain stability.

- Securing the Load: For items that could shift or roll, appropriate restraints (straps, chocks, non-slip mats) should be used to prevent movement during lifting and lowering.

- Clearance: Ensure adequate clearance from walls, racks, and other obstructions as the platform rises.

- Carelessness in loading, such as overloading or uneven distribution, can quickly cause the scissor lift table to become unstable, leading to a tip-over that endangers personnel and damages cargo.

- Strict Adherence to Manufacturer’s Operating Instructions: Each model of scissor lift table is unique, with specific operating parameters and safety features detailed in its manual.

- Operators must be thoroughly familiar with the manual for the specific lifting equipment they are using. This includes understanding the maximum load height, permissible wind speeds (for outdoor use), specific control functions, and any unique warnings or limitations.

- Do not assume that operational procedures are universal across different brands or models. Following these detailed instructions is crucial for safe and efficient operation.

- Mandatory Use of Personal Protective Equipment (PPE): Regardless of the task, personnel operating or working in the vicinity of scissor lift tables must consistently wear the appropriate PPE. This is a critical barrier against potential injury. Recommended PPE typically includes:

- Safety Helmets (Hard Hats): To protect against falling objects or overhead hazards.

- Safety Footwear: Steel-toed boots to protect against crushing injuries from dropped loads or equipment.

- High-Visibility Clothing: Essential in busy environments to ensure operators are seen by other machinery operators and personnel.

- Gloves: To protect hands from pinches, abrasions, or contact with fluids.

- Eye Protection: If there’s a risk of flying debris or splashes.

Elevating Your Operations with Safety and Precision

Electric scissor lift tables are indispensable pieces of lifting equipment for a vast range of industries. They excel at assisting with heavy-duty lifting, reducing strenuous manual tasks, and significantly enhancing operational flow. When acquired, maintained, and, most importantly, used properly and safely, these scissor tables can genuinely transform your workspace or project. They elevate efficiency, dramatically improve workplace safety, and contribute to a more productive and injury-free environment.

At Edmolift, we are proud to offer a comprehensive range of lifting solutions designed specifically for warehouses, manufacturing operations, and various industrial applications. Our scissor tables and other lifting equipment are engineered for durability, reliability, and ease of use, ensuring you achieve the best possible results with maximum safety.

To discuss how the right scissor lift table can revolutionise your operations, please do not hesitate to get in touch with our team today. We’re here to help you lift your business to new heights, safely and efficiently.