The Ultimate Guide to Material Handling Equipment

In today’s competitive business landscape, efficiency and safety are non-negotiable. For material handling businesses—whether in manufacturing, warehousing, or logistics—having the right equipment is not just an advantage, it’s a necessity. The right tools ensure smooth processes, protect your workforce, and boost productivity. This comprehensive guide will dive into some of the most essential equipment you need to keep your organisation running at its peak.

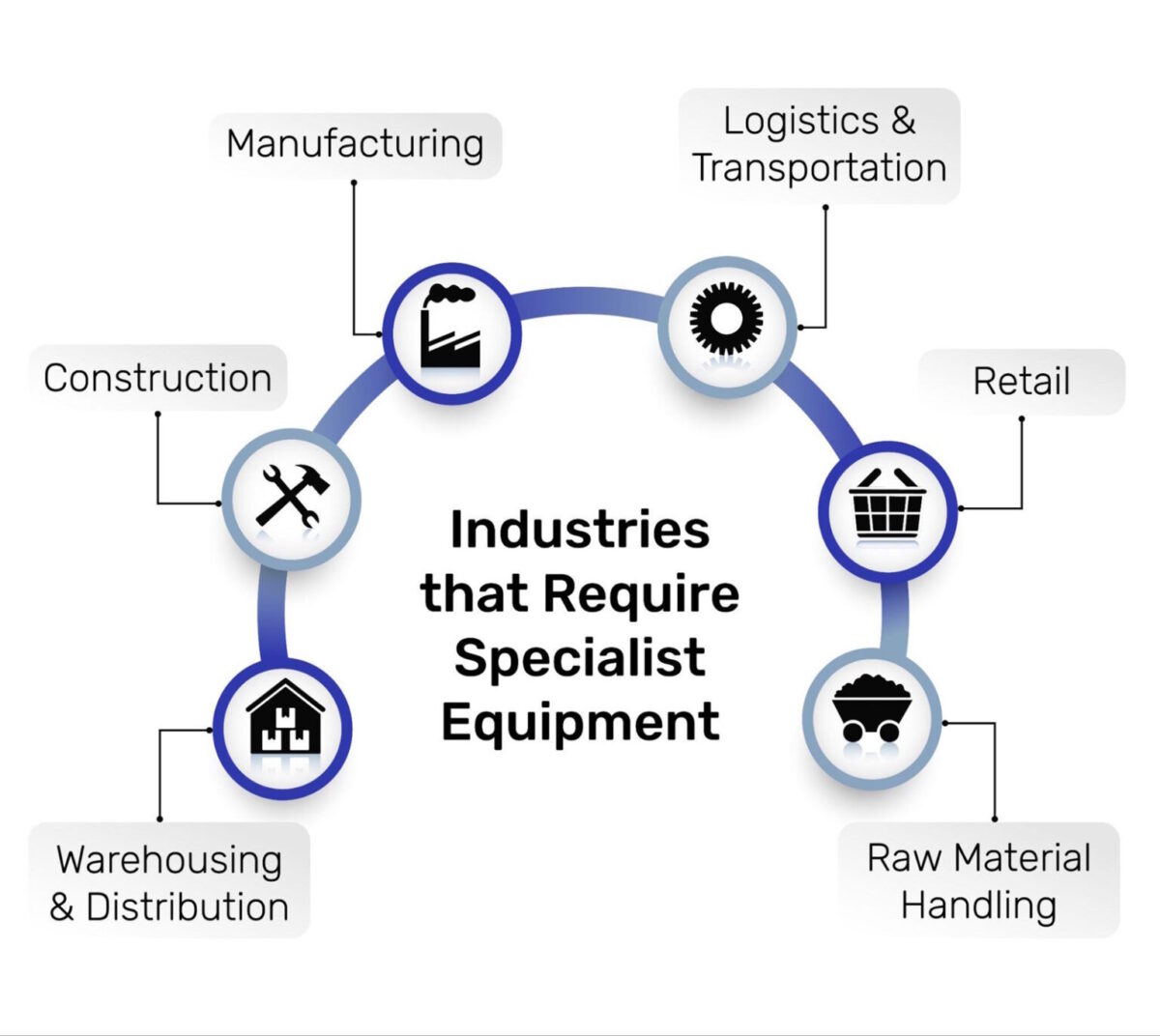

Industries That Require Specialised Material Handling Equipment

Specialised equipment is not limited to just warehouses. It’s a core component of operations in a variety of sectors, each with unique needs and challenges:

- Manufacturing: Essential for transporting raw materials, moving parts between assembly stations, and packaging finished products.

- Warehousing and Distribution: The lifeblood of these facilities, used for everything from inventory management and order picking to stacking and shipping.

- Construction: Crucial for lifting heavy materials, moving equipment on site, and ensuring the safety of workers at various heights.

- Retail: Used in back-of-house operations to manage stock, organise storage areas, and move large items from the storage room to the shop floor.

- Logistics and Shipping: The backbone of docks and shipping yards, where equipment is used to quickly and safely load and unload goods from trucks and containers.

Essential Material Handling Equipment For Your Site

While specific requirements vary by site and industry, a selection of the most common and useful equipment can drastically simplify processes and boost overall productivity.

Forklifts

Forklifts are the workhorses of any material handling environment. They are essential for moving, stacking, and lifting heavy materials over short distances. Beyond the standard counterbalance model, different types like reach trucks are designed for navigating narrow aisles, while order pickers are built to help workers retrieve items from high shelving. Having the right type of forklift for your specific operational needs is key to maximising efficiency.

Conveyors

Conveyor systems are an excellent tool for accelerating processes and reducing manual labor. These systems move goods from one area to another on a continuous belt, roller, or chain. In manufacturing, parts are transported through various assembly stages, while in e-commerce, sorting and packaging are expedited. They are invaluable for businesses that require high-volume, continuous movement of goods.

Scissor Platform Lifts

A scissor lift table, also known as a scissor platform lift or goods lift, is a highly versatile and crucial piece of equipment specifically designed for moving loads and products vertically. Its name comes from the criss-cross mechanism that expands and contracts, providing a stable, level lift. Unlike personnel lifts, a scissor lift table is strictly designed for material transport.

These lifts are indispensable in a variety of settings, from warehouses and docking bays to construction sites. They allow workers to lift heavy or bulky items to an ergonomic height, reducing physical strain and minimising the risk of injury. Whether you need to palletise products at a comfortable level, feed materials into a machine, or simply raise a load for easy access, a scissor lift table enhances both safety and productivity. Edmolift offers a range of options, from static models for assembly lines to mobile scissor lift tables for flexible use across a facility.

Work Positioners

Work positioners are mobile, compact lifting devices designed to lift heavy objects in tight or confined spaces. More agile than a forklift, they have adjustable heights and are extremely versatile. These tools are perfect for lifting components onto a workbench or positioning items for assembly, taking the physical strain off employees and enhancing safety in hard-to-reach areas.

Dock Equipment

Well-equipped docks are critical for any business involved in shipping or receiving goods. Dock equipment ensures the safe and efficient loading and unloading of goods. This includes items like dock levellers, which bridge the gap between the truck and the dock, and dock seals, which protect goods and employees from the elements. Quality dock equipment is essential for maintaining a safe and productive workflow for forklifts and other machinery.

Pallet Jacks

A pallet jack is a useful, maneuverable tool for transporting palletised materials. These machines use twin forks that slide under a pallet, using hydraulic force to lift it for easy transportation. Pallet jacks are ideal for smaller warehouses or retail stores where forklifts are too bulky. They are a simple yet effective tool for moving heavy loads safely over short distances.

Storage Containers & Bins

Storage containers and bins are useful items to have on your site, especially for organisation and storage. While they aren’t necessarily tools or machinery, storage containers and bins can be used effectively on large sites to store smaller items or goods that don’t require pallet storage. These containers can then be moved via hoists or cranes, depending on their size. This can help large facilities to stay organised, rather than having goods in random places. It will also help with freeing up floor space, and maintaining a safe work environment for employees.

Hoists & Cranes

Hoists and cranes are the heavy lifters of the material handling world, essential for moving and positioning extremely heavy or oversized loads that cannot be transported by forklifts. They are vital for construction projects, manufacturing plants, and shipping organisations where heavy-duty items need to be moved with precision. Proper training and safety protocols are paramount for anyone operating this powerful machinery.

Pallet Levellers

Pallet levellers are a type of mechanical device, which help to load and unload goods that need to be palletised. These devices will automatically raise, lower or tilt pallets to comfortable working heights. Rather than putting strain on employees, who could potentially suffer from injuries, pallet levellers keep the top of the pallet at an ideal level, so that employees can manually load or unload it. This helps to minimise the risk of injury, repetitive strain, or an employee handling an entire pallet, which would be too heavy to work with.

AGVs

AGVs, also known as automated guided vehicles, are a type of machine, which offer autonomous transportation of goods within a facility. These machines, or robots, use navigating sensors and predefined routes to transport goods and carry out tasks. AGVs are extremely useful on large sites, and could be the future of various industries. Their ability to operate without human intervention allows businesses to minimise labour costs, and employees can focus their time on other tasks. In assembly stations, and e-commerce warehouses, AGVs can be used to retrieve products and transport the relevant items around a facility.

The Broader Impact of Quality Equipment

Investing in high-quality material handling equipment has a ripple effect throughout your organisation. It’s not just about moving goods; it’s about building a more resilient, safer, and more profitable business.

- Enhanced Employee Safety: By reducing manual lifting and strain, equipment like a scissor lift table helps minimise the risk of workplace injuries, leading to a safer and healthier workforce.

- Increased Productivity: The right tools streamline processes, reduce wasted time, and allow employees to work more efficiently, directly boosting your overall output.

- Long-Term Cost Savings: While there is an initial investment, the long-term savings from reduced labour costs, fewer workplace injuries, and increased efficiency far outweigh the initial expense.

Achieve Peak Performance with Edmolift

Our article has thoroughly explored how different types of material handling equipment can be used to enhance workflow and improve efficiency. These tools will not only increase workplace productivity but also enhance employee safety and overall business output. In such competitive markets, investing in specialised equipment is how organisations stand out and become the number one choice.

When it comes to elevating your operations, a high-quality scissor lift table from Edmolift is a non-negotiable asset. As the leading supplier of ergonomic lifting solutions, we provide a range of quality products designed for safety, durability, and performance. Whether you need a simple goods lift or a custom-designed hydraulic solution, Edmolift has the expertise to support your goals. Contact us today to explore our full selection of scissor lift tables and other innovative equipment, and let our team help you find the perfect solution to elevate your business.